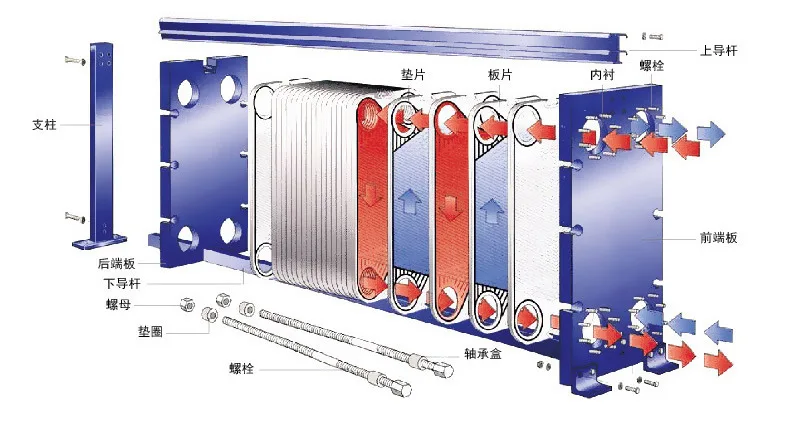

The product structure of Daniel's detachable plate heat exchanger

Components of a plate heat exchanger

Market and Application

For a long time, Jiangyin Daniel Cooler has been committed to providing high-quality plate heat exchangers for customers in the petroleum, chemical, industrial, food and beverage, power, metallurgy, shipbuilding, HVAC and other industries in many countries and regions. Currently, more than 20,000 plate heat exchangers are operating well in various industries.

The advantages of plate heat exchangers

Promote the flow of the liquid between the plates to form turbulence. Enable the metal plate to adapt to different pressures. The flow channel of the "herringbone" small pattern plate is composed of two adjacent plates with a herringbone Angle difference of 180 degrees. Therefore, there are many corner points between the plates, which can reach one point every 130mm ². The flow channel is not prone to deformation, has a relatively high pressure resistance, and can withstand a strong pressure difference. At the same time, since the flow is three-dimensional and the turbulence is relatively intense, the heat transfer coefficient is high.

|

Compact structure |

The space occupied by the plate heat exchanger is one of the smallest among all types of heat exchangers at present. Under the same heat exchange conditions, the floor area of the plate heat exchanger is only 1/3 to 1/4 of that of the shell and tube heat exchanger, and it does not require additional maintenance space when disassembled.

|

|

High heat transfer coefficient |

Due to the fact that the medium flowing in the plate group can form turbulence at a relatively low Reynolds number (Re), and fouling is less likely to form on the smooth plates, it has a very high heat transfer efficiency. In general water-to-water heat exchange, the heat transfer coefficient of the plate heat exchanger can reach over 6000w/m ² ℃, which is 3 to 8 times higher than that of the shell and tube heat exchanger.

|

|

High heat recovery rate |

Due to the high heat transfer coefficient, excellent flow ratio characteristics and completely reverse flow, the heat transfer temperature difference can be selected very low. Therefore, it is very suitable for the recovery of low-level energy heat. It is economically feasible to achieve a heat recovery rate of over 90% using a single plate heat exchanger.

|

|

Great adaptability |

The foldable plate heat exchanger has unparalleled adaptability. After installation, the metal plate group can be increased or decreased to meet the process requirements of expansion or contraction.

|

|

Low stagnant flow |

Due to its small flow channel and minimal stagnant flow, it can start quickly, respond promptly when control operations change, and significantly reduce the weight of the equipment.

|

|

Convenient for maintenance |

The design of the plates ensures there are no dead corners, so chemical cleaning can be carried out on-site without disassembly. For detachable plate heat exchangers, they can also be easily opened for thorough mechanical cleaning.

|

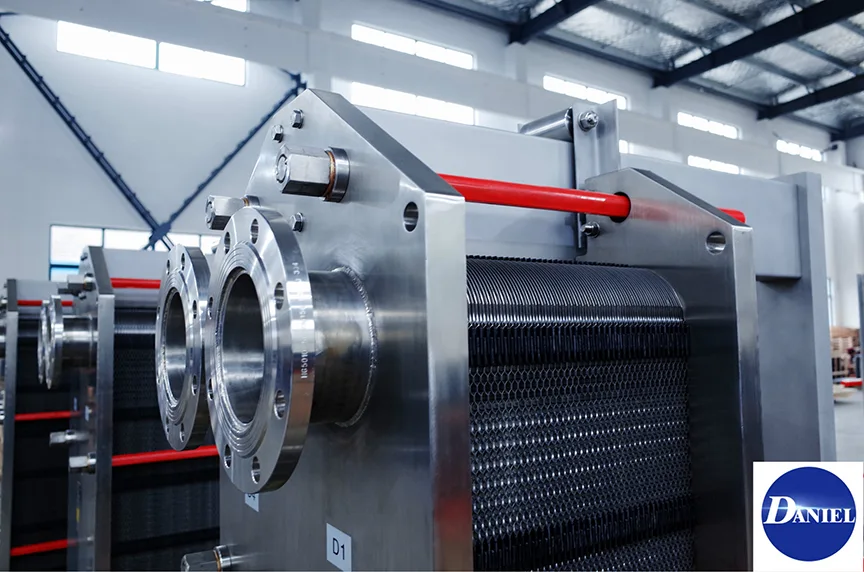

Jiangyin Daniel Cooler Co., Ltd. (Daniel Cooler) was founded in 2004. It is a heat exchanger manufacturer that produces detachable plate heat exchangers (PHE), heat exchanger gaskets (PHEGASKET), heat exchanger plates (PHEPLATE) and provides plate heat exchanger maintenance services (PHEMAINTENANCE).

Jiangyin Daniel Cooler has design and production technology and professional heat exchanger knowledge. Jiangyin Daniel Cooler has been committed to providing quality plate heat exchangers to customers in the petroleum, chemical, industrial, food and beverage, electricity, metallurgy, shipbuilding, HVAC and other industries in many countries and regions.

Special plate heat exchanger plates and rubber gaskets can be designed and manufactured according to customer needs

Plate heat exchanger rubber strip models: M3, M6B, M6M, M6MX-L, M6MX-R, M10B, M10M, M15B, M15Blip, MK15BW, M15M, M20M, MX25B, MX25M, M30, MA30M, MA30W, EC500, AM20, P31-HBM, AK20, C10, Clip6, Clip8H, AM30, MX25, Ec350, TL6B, TL10B, TS20M, TS6M, AM30, P22, P26, P31, P32, P36, A15B, A15M, A10, A10B, T20B, T20M, TS20M, P36, TL10B, T20P, clip6, clip8, clip10, AX30, AX30B, AX30BW, JWP26, JWP36, EC50, EC150, EC350, EC500.

Sugar industry, Metallurgical industry Heat exchanger rubber gasket, sealing gasket EC50, EC150, EC350, EC500, EC500-WTEL, EC500-WTFE, EC500-ETFC, EC500-TFR, EC50-WTEL, EC50-WTFEEC50-ETFC, EC50-TFR, EC350-WTEL, EC350-WTFE, EC350-ETFC, EC350-TFR,

Plate heat exchanger gasket model: T4, H17, N35, N25, SR2, N50, A055, J060, M92 (adhesive), J092, A085, J107, Q080, K34, K55, K71 (adhesive), P105, M60, P190, U2, E201, SR3, Q030, Q055, J185, SR6, H12, SR1, RS3

Plate heat exchanger gasket models: VT4, VT8, VT10, VT20, VT20, N40, VT40, VT80, VT130, VT1306, VT2508, VT2508 B-10, VT2508 B-16, VT2508 B NT250S, NT50X, NT100T, NT100M, NT100X, NT150S, NT150L, VT405, NT250S, NT250L VICARB

Plate heat exchanger gasket models: V10, V20 (button type), V20 (F paste), V45 (button type, paste type), V60 (paste type), V85 (paste type), V130 V4, V13, V20, V28, V45, V60A, V60B, V85, V85D, V100A, 100B, V110A, V130, V170, V280

Plate heat exchanger rubber pad model: GX-12, GX-12P1, GX-018, GX-26, GC-26, GX42, GC42, GC-30PI, GC-60PI, GX-51, GC-51, GX-60, GX-100, GX-180,

Plate heat exchanger rubber pad model: Sigma9, Sigma26, Sigma27, Sigma37, Sigma66, Sigma76, Sigma114, Sigma7, Sigma X29, Sigma M37, Sigma38, Sigma M66, Sigma 107, Sigma90SAL

Plate heat exchanger rubber sealing gasket model: S4, S7, S8, S9, S14, S15, S15FS, S21, S22, S30, S37, S39, S41, S43, S47, S50, S62, S65, S81, S83, S121

Plate heat exchanger sealing ring model: TL90PP, TL90SS, TL150PP, TL150SS, TL200PP, TL200SS, TL250PP, TL250SS, TL400SS, TL500PP, TL500SS, TL650PP, TL650SS, TL850PP, TL850SS

Plate heat exchanger gasket model: RX-70, LX50A, EX-15, EX-16, UX416, UX-01, UX-05, UX-20, UX-30, UX-40 can be designed and manufactured according to customer requirements

Special plate heat exchanger plates and rubber gaskets Main models of plate heat exchanger plates and rubber gaskets:

1. Plate heat exchanger plates. M3, M3 (N), M3X, M6-MFL, M6MD, M10 (MFML, MFGL, M10BD, M10BW), M10-BFGL, M15-(MFG, MFML, FFM, BFG), M15-MFGL, M15-BFML, M20-MFM, M20-MWFM, M20-FKMG, AM20-SFM, M30, MX25B, MX25M, AK20-FGL (E, F), A10 (B), A15, A15B, A15BW, A20, A20B, A3, A35, AX30, TS6, TS20, TL6, TL10, TL15, T20, C6, C8, C10. AC400. AC600, AV170, AV280 .

2. Plate heat exchanger plates A055.AO85, CHF130, H12, H17, H17PA, H17DS, J060, J092, J107, J185, K34, K55, K71, K71PA, M60, M92, M185, M107, N35, N35DS, N35PA, N50, Q030D, Q055D, Q080D, R10, R10G, R14, R14S, R23, R40S, R5, R55, R66, SR2, SR3, SR9, SR14, BR1.06, BR034, BR028, BBL1.6TAF, BBL1.6BF, BR1.08CF? N35, N25, N50, AO55, H17,

3. Plate heat exchanger plates: GX-51, GX-013, BR013 (trough type), GX-108, GX-214, GX-26, GC-26, UFX-26= GX-26GX-26, GX-51, GX-100, GX-60, GX-180, GC-26, GC-51... Vicarb (method G): V10, V20, V45, V60, V85... Sondex: S14, S15, S15FS, S21, S30, S41, S43, S50, S65, S83... HISAKA, W.Schmidt……..

4. Plate heat exchanger plates NT150L/N40/FA157/FA158/AF161/FA184NG/FA184WG/FA192NG/FA192WG/VT10/VT20/VT2

5. BR series plate heat exchanger plates produced in g BR series, BR005, BR01, BR03, BR05, BR08, BR13…

Application of Daniel plate heat exchanger gasket:

Ship industry: mainly used for cooling, jacket water cooling, lubricating oil cooling, piston coolant cooling, transmission oil cooling, heavy fuel oil preheating, diesel preheating, other process cooling, etc.

Power industry: heat exchangers are mainly used in open or closed cycle water cooling, transmission oil cooling, turbine oil cooling, lubricating oil cooling, piston and turbine and engine coolant cooling, diesel power station heat recovery, exhaust gas heat recovery.

Heat exchangers are mainly used in the pharmaceutical industry for: drug sterilization, emulsion cooling, suspension heating, plasma heating, citric acid heating, infusion cooling, etc., steel industry heat exchangers are mainly used in the steel industry for mold/continuous casting machine coolant cooling, hydraulic oil/lubricating oil cooling, machine coolant cooling, electrolyte heating and cooling, furnace water/feed water/emulsion/coking plant wastewater cooling, furnace body/electric j support/transformer coolant cooling.

Heat exchangers are mainly used in the HVAC industry for: district heating, domestic hot water, ice storage, constant heating of swimming pools, heat pump devices, heat recovery devices, heating water preheating, geothermal water/steam utilization, etc.

Heat exchangers are mainly used in the chemical industry for: heating and cooling of process media, oil cooling, electrolyte cooling, degreasing liquid heating, phosphating liquid cooling, etc.